As the world struggled with a pandemic in 2020, Ingenuitywas on its way to its destination, safely loaded onto the Perseverance rover.While NASA's "Mars 2020" mission was already a total of 38 missionsto the red planet, it was in many ways a pioneering operation. The very purposeof Perseverence's mission, which is to search for traces of past life and thepossibility of carrying out a future manned mission, is enough to stimulate theimagination. The tasks set for Ingenuity, although there are more engineeringthan fantastic visions, were completely groundbreaking. It was possible tocheck how the rotorcraft drive would behave in a lighter than Earth atmosphere,and the mission was a complete success - since the Ingenuity first broke offthe surface of Mars, it had already covered more than 2.5 km in a total of 12flights. And although only 5 flights were initially planned, it is alreadyknown that Ingenuity's mission has been extended indefinitely - we will hearabout his new achievements more than once again.

The history of Ingenuity is also full of fascinatingcuriosities. It uses a Qualcomm Snapdragon 801 processor - a twin similar tothose installed in HTC, Samsung or Oppo cells a few years ago. In addition, itruns on Linux 😉 The very name "Ingenuity" wasselected in the NASA contest "Name the Rover", which received 28,000responses from American high school students, and the winning name was VaneezaRuppani from Alabama. The most interesting, however, is the fact connecting thefirst flight to Mars with the first flight ... on Earth. While checking in atthe United States Space Agency, a chief engineer revealed a hidden package, thesize of a postage stamp. The package, placed under the solar panel, containsmuslin material that comes from the wing cover of the Wright brothers' planethat was the first to fly on Earth in history. It is already known today thatin the next missions sent to the red planet, flying machines will also takepart - probably larger and more complex than the simple construction of thepioneering Ingenuity.

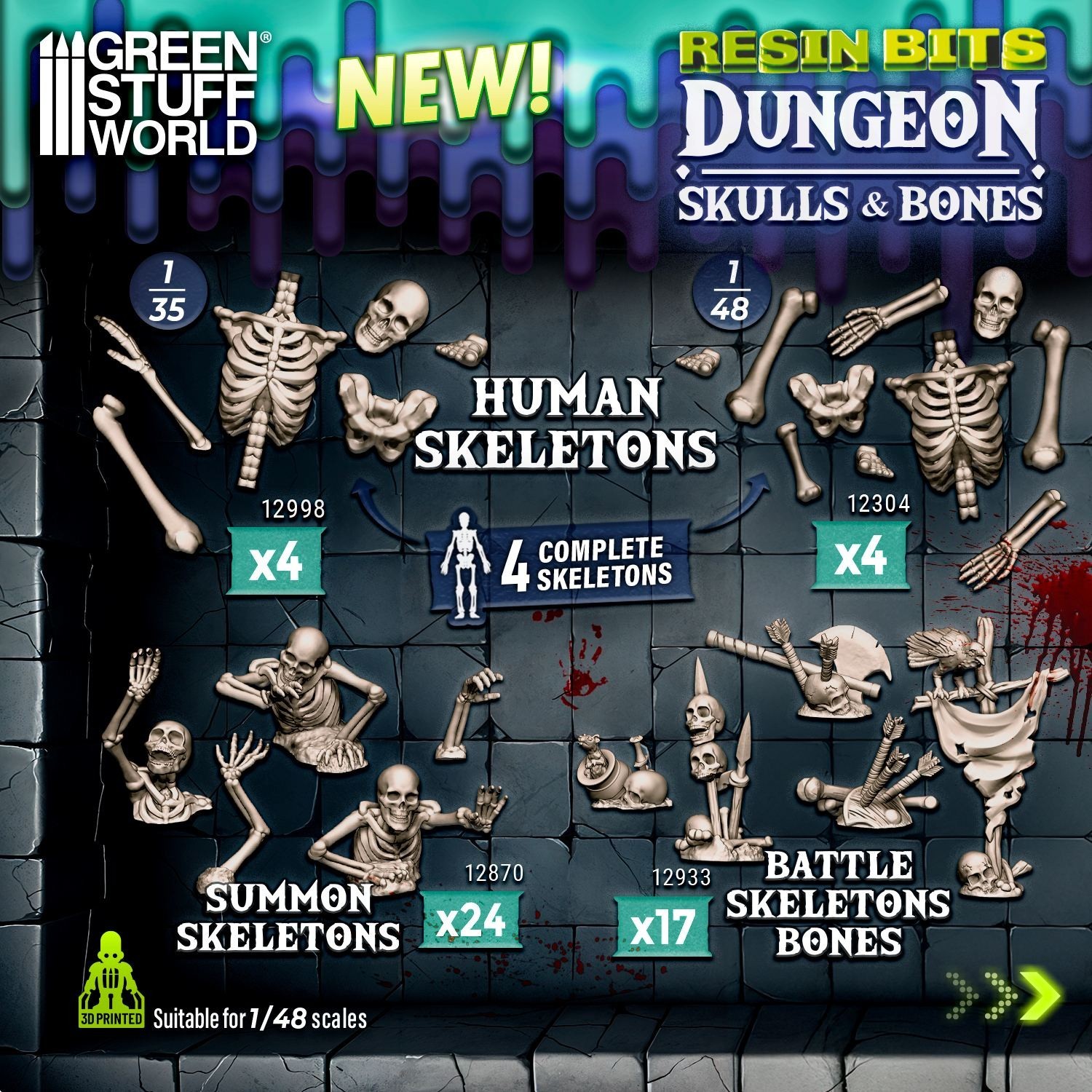

As for building the model from scratch, it is not completelycomplicated as you can see. The body was made of a polystyrene cube wrapped inaluminum foil, rotor mounting, solar cells, legs and leg connectors - fromphoto-etched and metal elements from other projects. For some details,GreenStuff also came in handy. However, the rotor blades were a challenge - tomaintain repeatability, it was not an option to carve them from scratch, and inaddition to repeatability, I also had to maintain the opposite profile of theblades of each pair. Finally, I chose a resin rotor blade set for He111 in1/48, which, after rework, worked quite well in its new role. To reflect thecarbon pattern on the blades, I used Tamiya carbon decal for cars in 1/24. Thepattern is similar, but its thickness turned out to be a problem - Tamiya'sdecal fix came in handy for laying on flat surfaces, and I made the edges withthe help of Bilmodel's 3. As for painting, there is no need to write about it:) I can only recommend quite successful MIG metallizers - I used 3 differentshades for the aluminum housing.